Configured with a balanced counter mechanism and a non-explosive opening mechanism, the TDP-NonEx completely eliminates the need for external personnel during any stages of an operation.

Utilizing over 15 years of TCO glass plug technology development and experience from over 1000 glass plugs installed worldwide, this latest generation of TCO’s NonEx glass plug is supported by the excellent track record of the TDP-3 and hundreds of remote openings of our non-explosive glass plug products.

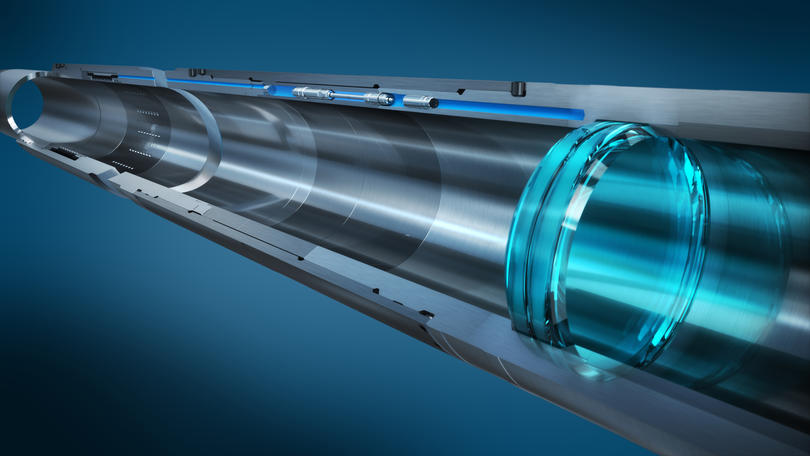

The TDP-NonEx incorporates TCO’s patented laminated glass design package to provide a reliable ISO 14998 V0 certified barrier. Extensive testing and field trials have been performed to qualify the product as a gas tight barrier while ensuring that the glass barrier disintegrates into small particles upon removal.

It also incorporates the debris exclusion membrane as used on our TDP-3 product to physically separate wellbore fluids from the counter mechanism. This membrane ensures that well bore fluids and potential contamination will not have any adverse effect on the remote opening mechanism of the plug. The balanced counter cycle mechanism was introduced to eliminate any need for well specific set up requirement. This, in combination with the explosives being removed, eliminates the need for any involvement by TCO during testing, assembly, running or opening. Workshop logistics are improved as the plug may be taken from the shelf, pressure tested as per the client’s requirements, mobilized to the rig site and installed by the main completion contractor or the client. A range of contingency removal options are available. Full ID is always guaranteed after opening.

FEATURES:

- ISO 14998 V0 certified barrier

- Laminated Glass Barrier to suit application.

- Hydrostatically Balanced Counter Mechanism

- Debris Extension

- Large Bore Access

- No Explosives

BENEFITS:

- Safer Operations

- No external personnel required

- Debris tolerant

- Lower Costs

- Intervention-free installation and removal

- Simplified workshop storage, makeup and transport logistics

- Reduced Rig Time

- Easy removal compared to deep-set/horizontal wireline plugs

- Large internal diameter

APPLICATIONS:

- Completion Test and Packer Setting

- Fluid Loss Control Device

- Intervention Free Completions

- Remotely Actuated Barrier Device

- Completion Barrier Plug

- Isolate wellbore while installing upper completion and displace to under balance fluid

- Qualified barrier for BOP removal and X-Mass Tree Assembly

Multiple cycles to open avoids the “tubing test pressure” being exceeded when remotely opening the plug.