Product: FA Valve Back Pressure Device

Location: West Africa

Challenge

The client experienced challenges with the previous system they used. They struggled with valves not supporting sufficient back-pressure to prevent U-Tubing, and valves not meeting the dual check valve barrier criteria. The client gave TCO a challenge with well specifications and short deadline. TCO were able to meet the requirements and the challenge. Within 2 months from first contact with the operator, TCO delivered a successful installation offshore, marking the first Chemical Injection System for TCO to be run in West Africa.

Solution

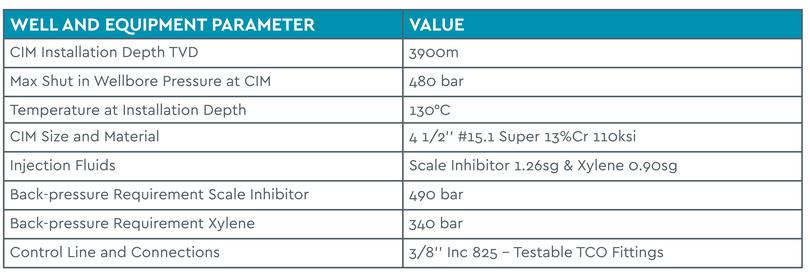

TCO’s Chemical Injection System was placed above and below a series of Gas Lift Valves with the lowest Dual Injection Point being situated below the Down Hole Pressure and Temperature Gauge. The TCO FA Back Pressure device was chosen to prevent U-tubing and to deliver continuous injection of Xylene and Anti-Scale Inhibitors throughout the lifetime of the well.

The FA Back Pressure valves is a unique absolute pressure device. The valve is autonomous which allows the back-pressure requirement to be incremented as the reservoir pressure depletes and the need for u-tube protection increases.

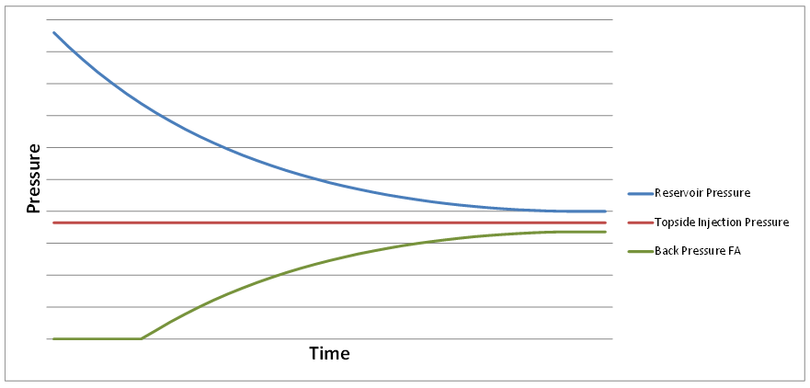

A standard back-pressure valve adds restriction to the system from day one, and for this application would result in surface injection pressure requirements exceeding the topside capacity during the early-production phase. The FA back-pressure device is passive in the early production phase when reservoir pressures are high, and only adds back-pressure when required as the well is depleted in late life phase. This ensures a continuous steady injection rate of chemicals down-hole, and a fixed positive injection pressure at surface through the full well lifecycle.

Result

TCO approaches chemical injection valve systems with a modular design. The chemical injection valve assembly consists of inline catch screens, an FA Back Pressure Device and the TCO ISO 14998 V0 dual check HN device. This design met the operator's dual check barrier requirement as the dual check HN are independent from the FA Back Pressure. The feedback from the operator after first installation was positive and TCO have won the contract to deploy the same system for all the remaining production wells on the field.