Brief outline:

-

E trigger

-

Full barrier in the well

-

Cycled open using smart electronical cycling

Location:

-

NCS

Introduction:

In the ever-evolving world of downhole devices, TCO's cutting-edge E-trigger takes center stage. This revolutionary technology has been meticulously developed to activate downhole devices with unparalleled precision and efficiency. Whether utilized independently or in conjunction with a mechanical trigger system, the E-trigger ensures redundancy and an extended operational window, offering a new realm of possibilities in the oil and gas industry.

One of the E-trigger's key advantages lies in its versatility. Designed to fit plugs in the TDP-3 range, the E-trigger also finds application in the Bypass Plugs showcasing its adaptability to diverse downhole environments.

The E-trigger boasts multiple smart activation mechanisms, providing operators with flexibility and control. Pressure cycles and pre-set or pressure-activated timers are utilized to activate the trigger, allowing for precise and efficient plug opening. This technology plays a crucial role in streamlining operations, reducing potential N2 consumption, and mitigating potential reservoir shocks during the opening process.

The following case study focuses on the latest successful application conducted in the NCS region where the E-trigger facilitated the seamless cycling open of a plug, redefining the possibilities in well production.

The Challenge:

One of the primary challenges faced in downhole operations is the need to avoid excessive time and N2 usage during cycling while ensuring minimal impact on the reservoir. TCO's E-trigger provides a novel solution, offering an intelligent cycling system that allows for plug opening at a predetermined pressure signature. This innovation not only reduces the time and N2 spent on cycling but also ensures faster and safer production in the wells.

The solution

The technology of the Electronical cycling system gives means of opening up the plug at a given pressure signature reducing time spent on cycling. This gets the wells faster and safer in production. The E trigger is customer configured for each specific application.

The result

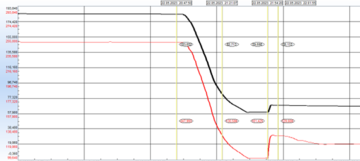

For this specific application the E trigger signature was started once the pressure in the well was bled down to the configured pressure window. From entering into the electronical signature only 33 minutes were used to cycle open the plug. The graph below shows a good indication of opening when pressure increases from 101bar to approx. 130bar.

Highlights:

This E-trigger case study showcased several impressive highlights:

-

Low Differential Pressure: The E-trigger demonstrated minimal differential pressure when opening the glass plug against the reservoir, ensuring smooth and controlled operations.

-

Time and Cost Savings: The smart setup of the E-trigger significantly reduced operational time and costs, adding substantial value to downhole operations.

-

Reduced N2 Handling: With a streamlined cycling process, the need for extensive handling and storage of N2 on the rig was minimized, further enhancing operational efficiency.

Conclusion:

The TCO E-trigger has undeniably redefined downhole operations with its intelligent and efficient activation mechanisms. By combining innovation, adaptability, and customer-focused configuration, TCO continues to pioneer advancements in the oil and gas industry, promising a brighter and more efficient future for well production and exploration.