Product: TDP-2 Completion Barrier Plug

Location: Gjøa, Norway

Challenge

During the development of the Gjøa wells, barrier isolation plugs were required to seal off the reservoir prior to start-up. Conventionally, a drilling or intervention unit is required on site when these plugs are to be retrieved. GDF Suez therefore required a solution that would enable the barrier plugs to be remotely removed from the production platform, kilometres away from the well location, in order to eliminate the need for a costly mobile unit.

Solution

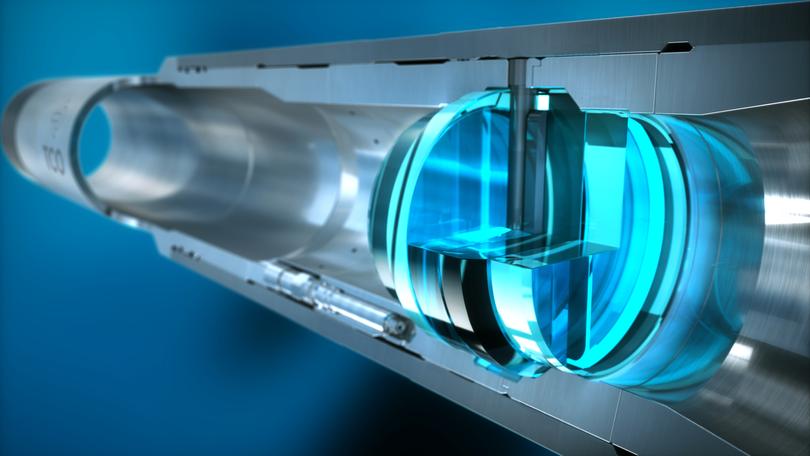

The TDP-2 was developed from TCO's original TDP barrier plug, and features improved installation and remote cycling capabilities. The TDP-2 makes use of TCO's patented laminated glass material, built into an ISO 14310 V0 certified barrier plug package. This provides a total seal against all gases and fluids, even under extreme conditions.

During the production phase, GDF Suez decided to remotely open and clean-up the last two gas wells in the Gjøa field, B-2 and D-3. By opening the wells from the Gjøa platform in cooperation with Statoil, GDF Suez avoided rigging up the well test package and running the work over riser on the Transocean Searcher semi-submersible, which had drilled both the wells and completed B-2. This meant that the rig could go straight from the completion of well B-2 to start the completion of well D-3, while B-2 was handed over to the GDF Suez petroleum engineers onboard the Gjøa platform. After testing the necessary subsea valves and production choke, the TCO supplied TDP-2 glass plug in well B-2 was cycled open by applying pressure down the glycol injection line to the wellhead. A pre-set nine cycles of 250 bar were performed before the TDP-2 opened as planned and the well was cleaned up to the production facility.

While well B-2 was being cycled open, the Transocean Searcher completed well D-3 with a TDP-2 in the lower completion, acting as a packer setting device and a barrier plug. After completion of the well the Transocean Searcher was released, and the TDP-2 glass plug was remotely cycled open and cleaned up to the production facility.

Result

By performing this operation from the Gjøa platform, GDF Suez avoided rigging up well testing equipment and performing two runs with the work over riser, which meant the company not only saved time and resources but also eliminated the HSE risks involved in such operations. Since the wells were able to produce into the permanent production equipment, this eliminated the risk of spills, and the hydrocarbons produced during clean-up could be sold rather than flared off. The Transocean Searcher was also released 14 days earlier, freeing up rig time for other operations. In total, GDF Suez estimate the savings gained from this successful operation to be in the range of NOK 80-90 million / around USD 12 million for the two wells.