Conventional approaches constantly relieve pressure as the B-annulus pressure “tracks” the A-annulus pressure. Such constant pressure relief reduces the life of the well, risks barrier integrity and alters the supporting pressure inside and outside of the casing.

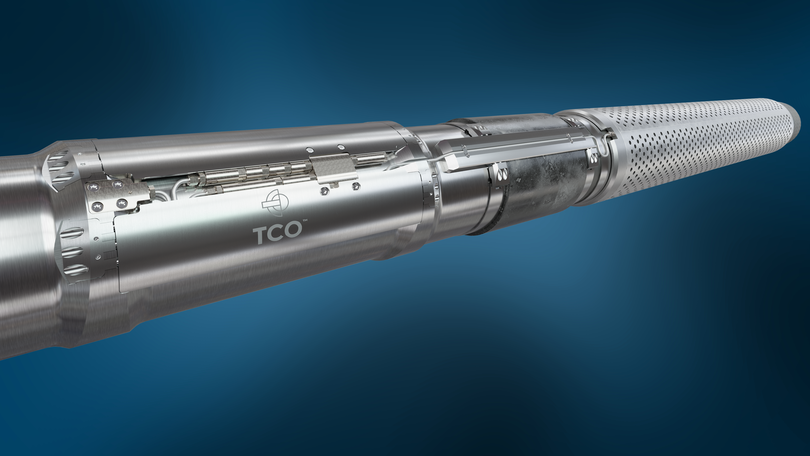

TCO’s patented Annulus Pressure Relief System makes the B-annulus pressure independent of the downstream back pressure in A-annulus, given that the B-annulus is greater than in the A-annulus and the relief valve opening pressure. This unique feature means that the volume that is bled off from B to A-annulus and the resulting pressure in B-annulus can be pre-determined through the relief valve setting.

The result is a reliable bleed of volume and a desired and known resulting B-annulus pressure, allowing for maintaining the production casing barrier and the B-annulus pressure support.

Features and Benefits

- Prevents casing collapse due to pressure build-up in B-annulus

- Prevents casing burst due to loss of pressure support in B-annulus

- Maintains production tubing barrier after activation

- Quick and simple installation as integral part of casing string

- Maintains desired B-annulus pressure

- One-way communication from B-annulus to A-annulus

- Enables controllable bleed-down of a B-annulus pressure

- ISO 14998 V0 qualified gas-tight barrier from A-annulus to B-annulus

- Equinor TR2385 qualified

Applications

- Subsea production wells with APB and without access to bleed off B-annulus to surface

- Wells where B-annulus monitoring is deployed, allows for monitoring and mitigating action

- Replaces conventional approach of using burst disks or check valves between A-annulus and B-annulus

- Replaces use of crushable foam on inner casing as allows pre-set B-annulus maximum differential and minimum absolute pressure

- Standard and Sour Service wells 110ksi-125ksi rating, -APRS is matched with casing specification