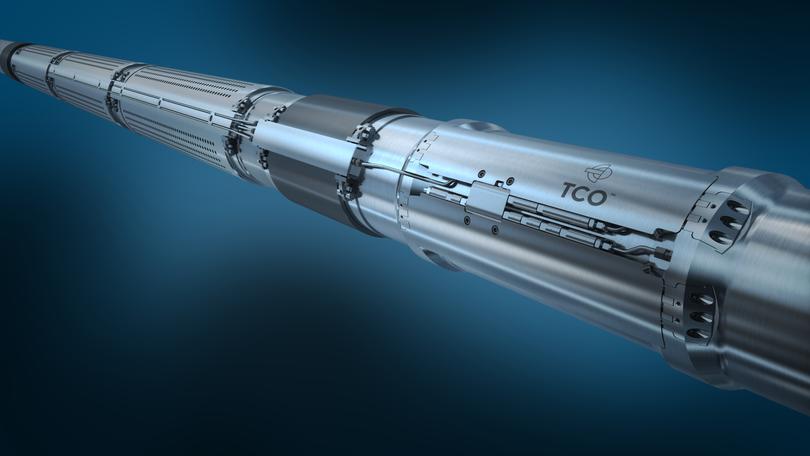

Product: Annulus Pressure Relief System (APRS)

Location: Norwegian Sea

Challenge

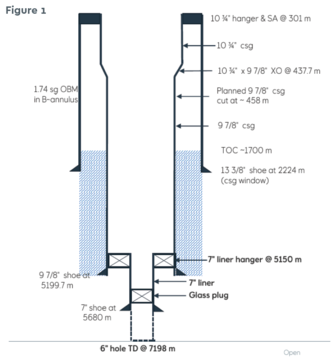

A major Norwegian operator experienced a trapped volume between the 9 7/8” and 13 3/8” during the cementing operations for a subsea well. The operator experienced that the 9 7/8” x 10 ¾” casing was cemented into the 13 3/8” annulus, creating a closed B-Annulus volume.

The pressure trapped in the B-annulus was 250 bar. During start-up of the well it was simulated that the pressure on B-Annulus side would increase to 550 bar due to thermal expansion, ultimately leading to a collapsed 10 ¾” casing.

The original plan was to have an open shoe that would bleed of excessive B-annulus pressure to the formation. Due to the long vertical section and the long cement job, the risk of cementing the 13 3/8’’ shoe was present and caused the shoe to be cemented off.

Solution

TCO was contacted by the Operator to help eliminate the risk of collapsed casing due to annular pressure build-up.

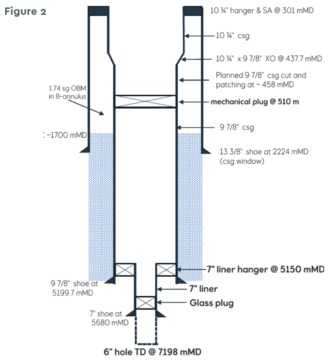

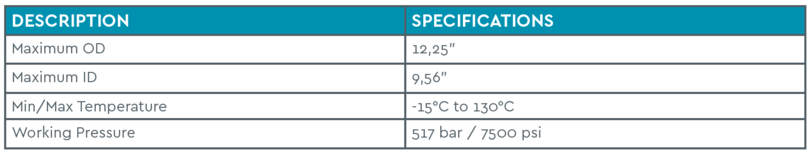

The proposed solution from the Operator was to cut and pull the 10 ¾” x 9 7/8” casing at approx. 458m and re-run casing with the TCO Annulus Pressure Relief System (APRS) installed below the 10 ¾” tubing hanger.

To be able to include the APRS, the 9 7/8” casing needed to be patched at the cut point to obtain the pressure integrity as a production casing.

A GTV plug was run in hole below the cut point to ensure that debris from the cutting process did not intervene with the current lower completion equipment already installed in the well. (see figure 2 ). Once the GTV was in place the cutting and patching operations could be initiated. First run was done with a casing cutter, 2nd run with a spear. On the third run the patch overshot could be installed, this assembly included the TCO APRS.

The APRS was pre-set to open at 210 bar B-annulus pressure. Once pressure on A-annulus is lower than B-annulus, the APRS will start to bleed off excessive pressure from B-annulus to A-annulus until safe pressures are reached, thus avoiding potential casing collapse. The APRS includes V0-rated check valves to prevent flow communication from A to B-annulus. Once the patch with APRS was installed, the GTV plug could be removed and the well completed as planned.

Result

Since the APRS could be rush mobilized to meet the customer needs, the well did not have to be suspended or plugged for a longer period of time. The TCO APRS ensures that there will never be a higher differential pressure than 210bar between B-and A-Annulus, so that the risk of casing collapse is mitigated during the startup phase of the well.

In similar operations or applications where the risk of annular pressure build in B-annulus is present, the APRS can mitigate the risk and be run as part of the casing without needing additional accessories. This includes but is not limited to, subsea wells with known trapped B-annulus pressure, wells where annulus is in high risk of barite

sagging and long vertical cemented sections with risk of plugging the casing shoe and formation bleed-off option.

The TCO APRS is Equinor TR2385 qualified, and field proven for multiple licenses within Equinor.

Contact

If you want to know more about the APRS, please contact:

Ole Petter Waage

Product Line Manager

E-mail: Ole.Petter.Waage@tcogroup.com